Current supply chain issues are affecting every aspect of daily life, from inflation to housing to rising costs of gas and food. A record number of ships are waiting to unload at U.S. ports, causing massive backlogs and worsening shortages. For breweries, wineries, and other alcohol producers, supply chain problems can have a ripple effect on all business functions, from difficulty sourcing raw materials to distribution slowdowns. As vendors raise prices on vital supplies like cans, producers are often forced to raise prices to keep the business viable, and the cycle continues.

It’s difficult to get to the bottom of what’s causing these supply chain problems when we’re dealing with a widespread issue across many distinct industries. But there are a few main causes of supply shortages, and most of them can be traced back to the COVID-19 pandemic. With more information on the causes of supply chain problems, we can explore the most effective ways to avoid business disruption due to supply shortages./

What’s Causing Supply Chain Issues?

- Delayed effects from disruptions early in the pandemic. When COVID-19 became a global, acute crisis in spring 2020, the economic effects were profound. Millions of people lost their jobs, entire industries closed their doors, and retailers were left to adapt to fluctuating, unpredictable demand. Some of the shortages we’re experiencing now are actually the delayed results of the economy’s rapid contraction a year and a half ago.

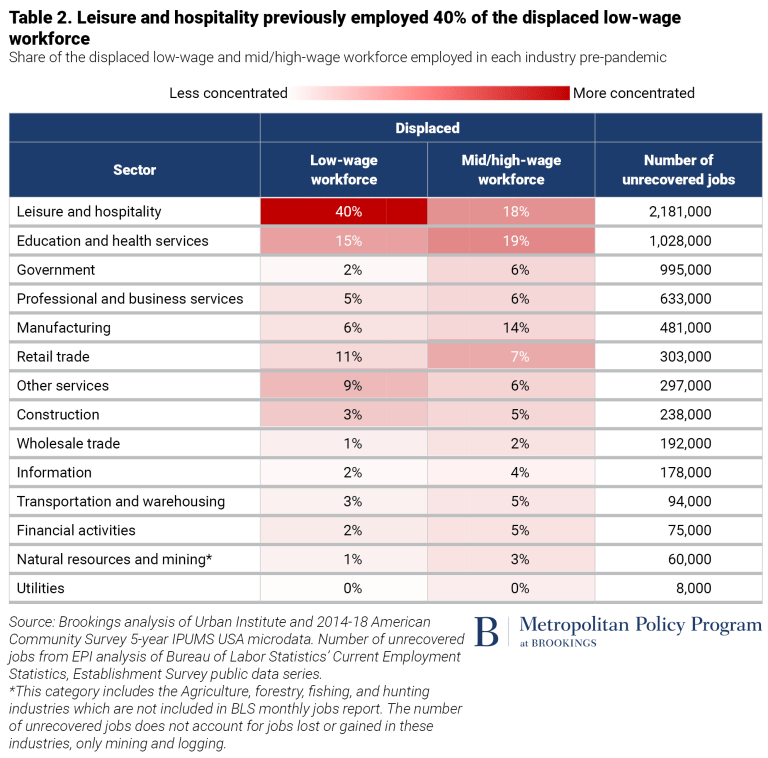

- Labor shortages. Similarly, early in the pandemic, the labor market was thrown into flux. Q2 2020 saw the unemployment rate reach a whopping high of 13% before stabilizing as the economy recovered. Job losses were not evenly distributed across demographic categories, with young people and low-wage workers being hit hardest. The industry with the second-highest unemployment rate, after the service industry, was production, transportation, and logistics. Faced with the prospect of months of unemployment, many individuals in these industries moved on to other jobs. Now that demand is booming, the transportation industry can’t find enough workers to grow accordingly, contributing to shortages and rising costs. As long as there is a labor shortage in the logistics sector, supply chain issues are likely to continue.

- Rise in demand. As the economy has returned to something resembling normalcy in the last several months, we’ve seen an explosion of demand for everything from cars to luxury items. It’s a result of pent-up demand from the height of the pandemic, when shopping was limited to the essentials and many people had little to no disposable income. But as demand has grown, the market has struggled to produce enough supply to keep up, leading to increased prices and of course…

- Inflation. When demand outpaces supply across the board, prices for goods go up, both in retail for consumers and for wholesalers. This leads to still higher prices and, eventually, inflation. October 2021 saw a 30-year high in inflation at 6.2% over last year. With the holiday shopping season looming and few tools to control rising inflation, prices will likely continue to rise and supply chain issues will continue.

Supply Chain & Alcohol Production

With supply chain issues touching every industry, those of us in alcohol production are no exception. In general, the more complex the product, the more difficult it is to deal with supply chain fluctuations. (Side note: That’s the reason that the auto and housing industries have seen some of the largest impacts from the supply shortages.) Here are some of the ways the supply chain crisis is impacting alcohol producers specifically.

Difficulty Securing Raw Materials

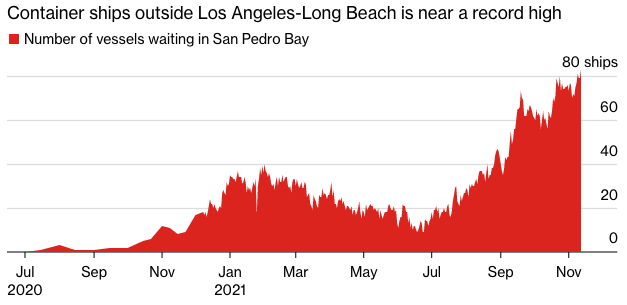

Between slowdowns on deliveries and container ships waiting weeks to unload, it’s becoming increasingly challenging to reliably source raw materials needed for alcohol production. Ingredients like hops and other grains are perishable, making them even more vulnerable to logistical bottlenecks. Alcohol producers also often source raw materials from overseas, and the further ingredients have to travel, the more unreliable they are during this time of delivery slowdown. This compounds a season of shortages that began with diminished grain yields this summer because of heat and drought.

Packaging & Bottling

Breweries, wineries, and distillers across the country are seeing shipping delays for packaging materials that normally arrive like clockwork, thanks to logistical problems from the supply chain fiasco. Glass bottles and cans are in short supply, and other materials like printed labels are also affected in many cases. Many producers have been left scrambling, with no containers for their product and no way to predict what next season will bring in the wake of these shortages.

Rising Costs

Dealing with delivery slowdowns and shortages of materials is challenging enough. But costs are also skyrocketing, even as deliveries become less reliable. The average cost per shipping container is up 145% over pre-pandemic levels. Producers at every level of the supply chain are raising prices to compensate, and so alcohol producers, with their narrow profit margins, also have to pass prices on to consumers to stay in business.

How to Mitigate Supply Chain Effects

Here are a few ways that craft alcohol producers can mitigate rising costs and shortages as a result of the supply chain crisis.

Plan for Delays

If you haven’t yet had problems sourcing materials for production, it’s safe to assume that you will at some point in the coming months. The supply chain is backed up to such a degree that experts expect it won’t start to return to normal until spring of 2022 at the earliest. For bottles and other non-perishable goods, order more than you need to contribute to a stockpile in case of worsening shortages.

Expand Your Business Model

It’s always a good idea to diversify your revenue streams. Variety offers an extra level of insulation against market fluctuations that can occur as a result of supply chain challenges. If you’re struggling to get your bottled product to retailers in a timely manner, consider switching distributors. You could also branch out into direct-to-consumer sales via an app, your website, or by selling locally.

Explore New Suppliers

Even if you’re not ready or willing to drop your current suppliers completely, it can’t hurt to form a working relationship with other vendors. That way, if one of your suppliers is experiencing extreme delays, you will already have contacts with other suppliers who can step in and help your business meet a short-term need.

Stay Flexible

Necessity is the mother of invention. Shortages can be an impediment to normal business operations, but they can also provide an opportunity for innovation. If your team stays agile and works to solve supply shortages with creativity, you may just stumble upon your next bestselling product or a fun new way to package your wine or beer.

Communicate With Customers

If you experience production delays or have to increase prices due to the rising cost of materials, use your platform to talk to customers and explain what’s going on. Whether you connect with customers on social media or through an email newsletter, transparency is the way to go. Be honest about supply chain struggles. Chances are, your customers will understand, even if you are raising prices. Prices are going up in nearly every single industry thanks to inflation, so it’s safe to say that you won’t be the only business working to adapt.

With the rise of new COVID variants and the backlog of goods due to bottlenecks at ports, it’s hard to say when we’ll see the supply chain return to normal. But in the meantime, there are things your business can do to mitigate ill effects from the supply chain crisis.