As a brewer, your focus is on making the best beers for your customers. TTB reporting, paperwork, and other record-keeping tasks pull you away from the brewhouse and into the office. While these tasks can be time consuming, they’re an essential part of the job.

From maintaining historical data and recipes to making it easier for your team to work collaboratively, you couldn’t do your job without these records (and neither could your coworkers). But something as simple as spilling your coffee on yesterday’s logs can set your team back days and leave them guessing fermentation data. Are your records accident-proof?

Read on to learn how you can improve your record-keeping skills, gain powerful insights from your data, and even go paperless in your brewery.

Table of Contents

Benefits of Better Record-Keeping in the Brewery

Better Beer

Let’s start with the part that matters most to you: the beer. With better record-keeping practices comes the ability to easily access data from years past. With this historical data at your fingertips, you can extract insights on what works and what doesn’t. In turn, your beer gets better. Referencing last year’s batch of your most popular seasonal can mean the difference between a smash hit and an okay beer. On the flip side, having access to your typical recipes can empower you to always be improving and experimenting in the brewhouse.

Easier Problem-Solving

Keeping more accurate records means that errors and surprises are easily resolved. Error-free records can show you exactly where things went awry and give your team the agency to fix problems quickly and efficiently. Without clear record-keeping, you might never learn what caused your latest kegs to cost $2 more than usual to produce.

Massive Time-Savings

Organized, up-to-date records mean that you won’t have to dig through stacks of paper or last week’s sticky notes to find the data you were looking for. Spend that time researching new styles to try or helping the new production worker get comfortable with your space. Plus, we didn’t even mention TTB reporting. With the right record-keeping process, you can fill out most of your TTB reporting in minutes instead of hours or days.

What Information Should Brewers Record?

While no two breweries are the same, there’s a lot of overlap when it comes to overall processes in the brewhouse. Here’s a list to get you started.

- Inventory shipments: Raw materials like hops and grain, packaging supplies, merch, and more. Keeping track of your inventory from the moment it arrives at your facility will set you up for success when it comes to pricing and overall organization.

- Fermentation metrics: You’re likely already checking your beers’ gravity, temperature, and pH on the regular — keeping these on record is helpful to your historical data and finding abnormalities later on.

- Production tasks: Moving beer from tank to tank, adding ingredients, etc. All of these production tasks are essential to record, especially if you’re working with a team.

- Sanitation tasks: Keeping track of cleaned kegs and tanks keeps your brewhouse safe and clean.

Record-Keeping Methods for Brewers

With so much information to track and so little time, how do breweries track essential production data as the beer gets brewing? Most brewers rely on a combination of manual and digital methods to stay on track, so let’s dive in so you can pick the right solution for your brewery.

Whiteboards

Whiteboards are an incredibly popular method for tracking data in the brewery, especially when it comes to production tasks. Checking the status of each tank on a whiteboard can work well for a one or two-person team, but as your team grows, whiteboards just might not cut it. Without any accountability options available on the whiteboard, plus how easy it is to accidentally erase valuable information, whiteboards are a great starting point, but difficult to scale.

Paper Records & Notebooks

Paper records and notebooks provide a clear, unmoving record of important data for the brewery. Many brewers will track data points on clipboards hanging from tanks and in their trusty notebook. Like whiteboards, this solution is a great place to start. When you have fewer filled tanks and fewer hands touching your data, paper records can be a pretty reliable source for tracking in the brewhouse. But they bring growing pains. As you look to scale your operation and add complexity to your lineup, paper records can hold you back. Something as simple as a spilled shift beer can keep you from developing great recipes and learning from the beers of years past. Not to mention, you could be missing vital information if you’re ever audited by a compliance authority.

Spreadsheets

Many breweries will turn to spreadsheets as they have more data to track and more people working with their product. After all, the appeal of multiple sheets and a digital record is real (because let’s face it, reading other people’s handwriting can be exhausting). We all know the value of having a spreadsheet whiz on your team. Complex formulas and exact data points make spreadsheets a viable option for tracking brewhouse stats.

On the flip side, spreadsheets make scaling your business difficult and bring the added complications of corrupted data and turnover in the brewery. What happens if the spreadsheet builder heads to another brewery? Hiring someone just to format your data and keep it alive from computer to computer is a big expense for little return. Don’t limit your team to the expertise of one employee and the hope for working spreadsheets. Plus, who wants to walk around the brewhouse holding their laptop? Spreadsheets are difficult to edit on the go with a tablet or phone, making a laptop holder seem like a viable purchase for your team… don’t go there.

Software

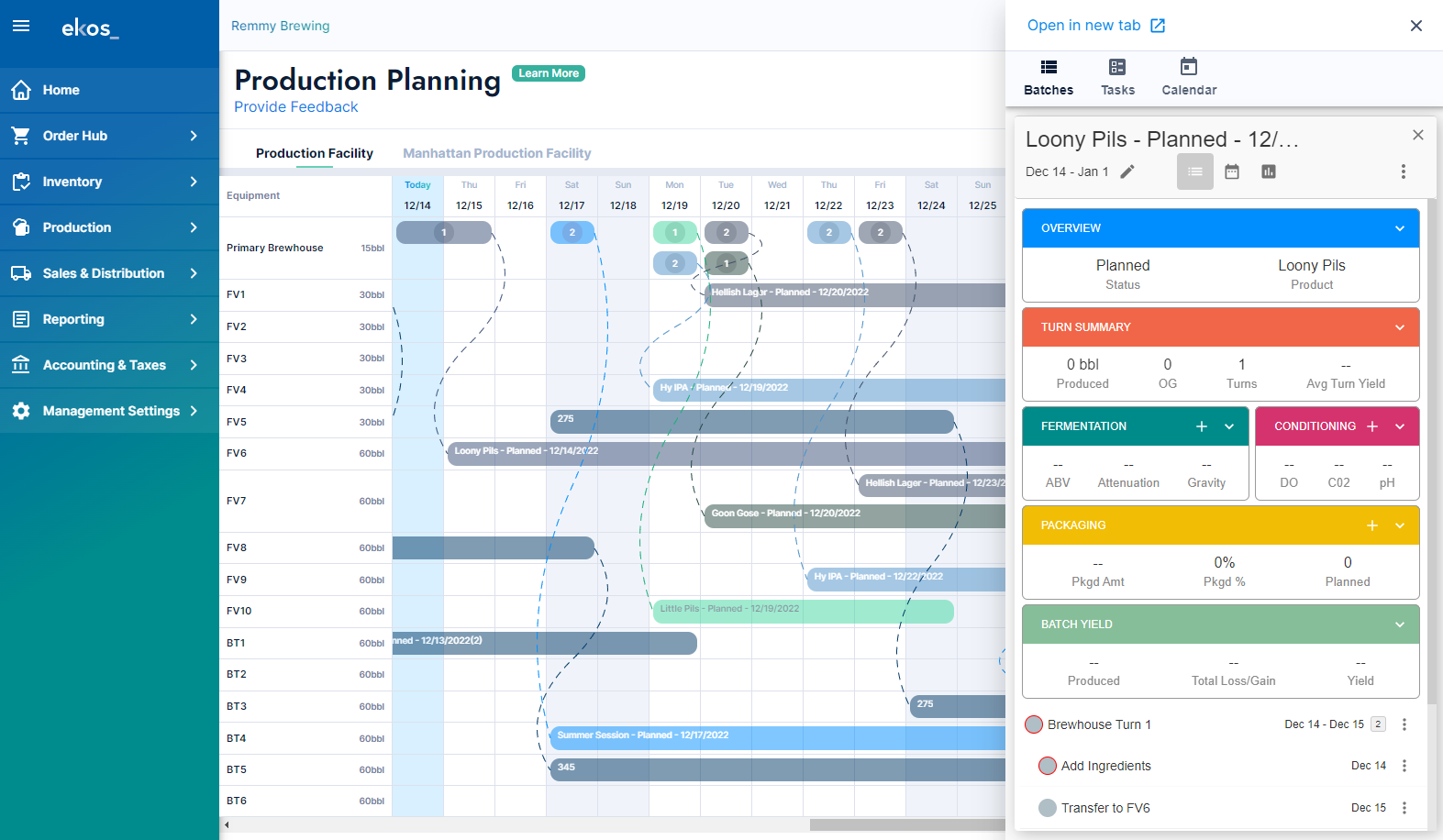

If you’re looking to really step up your game and go paperless, brewery software is your best bet. Using a cloud-based system that allows for collaboration among your team can open the door to better, newer beers with the time savings and seamless connection software can provide. Plus, software offers a better workflow and more visibility into daily tasks. The ability to assign tasks and see them completed from shift to shift can give your brewhouse’s leadership peace of mind that essential tasks are completed even when they’re away from the brewery.

On top of its collaborative nature, using software designed specifically for breweries means you don’t need to build out a spreadsheet with all-new column titles and formulas to ensure your data is protected. Brewery management software is already built with the capacity to track fermentation logs, visualize and plan your production runs, and keep a tight leash on inventory management.

Implementing brewery management software of course takes time and money, but it’s an investment that will pay off in the long run. Whether that’s improved communication and production planning or hard dollars in the bank account after avoiding a mix up in the inventory side of the house, brewery management software is a worthwhile investment that can empower your team to do their best work.

Ready to Learn More About Brewery Software?

Ekos is the leading brewery management software in the U.S. and Canada — more than 18,000 users trust our software to help them manage their day-to-day operations when it comes to inventory, production, sales, and accounting.

Ready to learn how your brewery can benefit from using Ekos? Check out a quick product tour on your own or contact the sales team to learn more.