The craft spirits industry continues to expand, with new distilleries opening across the country each year. If you’re crunching numbers and feeling overwhelmed by spreadsheets and startup guides, you’re not alone—many entrepreneurs asking “How much does it cost to start a distillery” or researching micro distillery startup costs find themselves navigating a complex web of expenses, legal requirements, and regulatory compliance.

The answer depends on various factors—from location and production capacity to business model—with total investments of up to four million dollars. According to the American Distilling Institute, success requires proper planning, comprehensive legal guidance, industry-specific training, and strong operational systems.

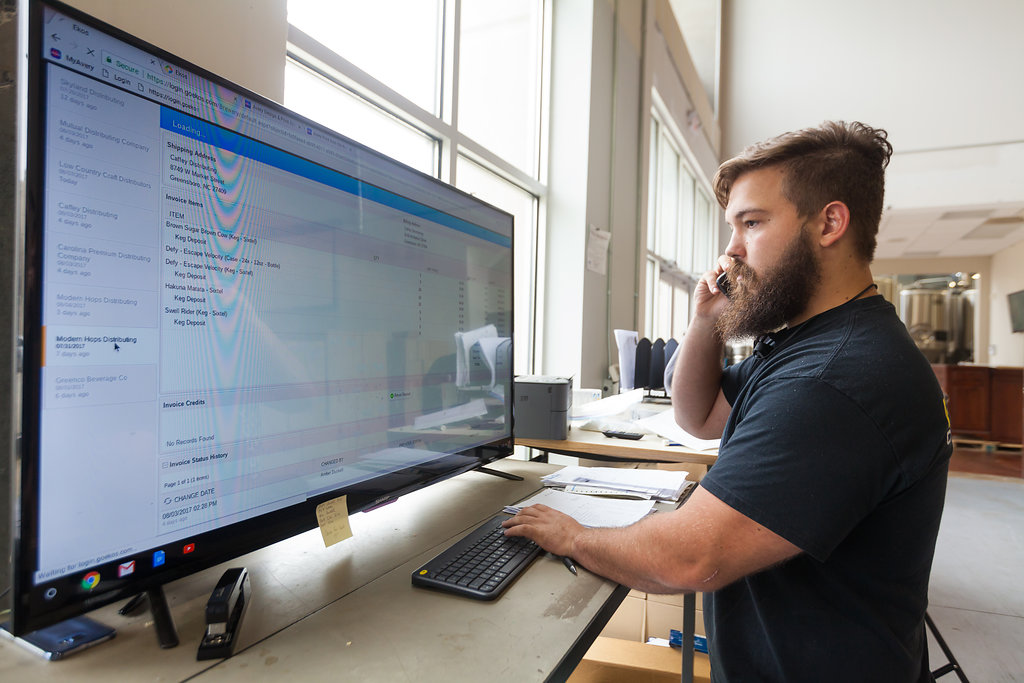

Modern beverage software helps streamline the complex processes that keep your distillery up and running after you’ve opened the doors, making it easier to manage costs, track compliance, and run your operation efficiently.

How Much It Costs to Start a Distillery: Startup Planning and Investment Considerations

Understanding distillery startup costs requires meticulous financial planning and understanding of both immediate and ongoing costs, including regulatory compliance. Your precise budget will hinge on your spirits portfolio, target market, and growth strategy. Strategic decisions around still selection, aging facilities, and operations will shape not just your startup phase but your long-term profitability.

Size and Scope of Operations

Your production goals set the foundation for all other cost considerations. A craft distillery focusing on premium spirits might start with a 500-gallon still system, while larger operations could require 1,000 gallons or more. Remember to factor in aging warehouse requirements—spirits like whiskey need significant storage capacity for barrels. Your aging capacity requirements will directly impact facility size and costs.

Geographic Location and Market Analysis

When calculating how much to start a distillery, location impacts more than just rent or mortgage payments. Different regions have varying utility costs, labor rates, and competition levels. Urban locations typically command higher prices but offer greater foot traffic, while industrial areas provide more space at lower costs but may require additional marketing effort to draw customers.

Location and Facility Requirements

Your facility choice significantly impacts your distillery startup costs and ongoing operations. Unlike many other businesses, distilleries face strict regulations about where they can operate and what safety measures must be in place. A thorough facility assessment should evaluate several critical requirements:

- Proper zoning for alcohol production: Many areas have specific requirements for distillery operations

- Adequate utilities for distillation processes: High-capacity water, gas, and electrical systems are essential

- Fire safety compliance capabilities: Specialized systems required for handling flammable materials

- Space for aging warehouses: Temperature-controlled areas for barrel aging and storage

- Loading dock access for deliveries: Facilitates efficient movement of materials and finished products

Pro tip: Look beyond just rent costs. Some successful distilleries choose locations with higher upfront costs that prove more profitable due to better customer access and distribution capabilities.

A well-planned facility layout should accommodate your immediate production needs while allowing for future expansion. Consider proximities between production areas, aging warehouses, and your tasting room. This strategic planning helps prevent costly modifications later and supports efficient operations as you grow.

Distribution Strategy Planning

Your chosen distribution model significantly affects startup costs. Self-distribution offers higher margins but requires investment in vehicles, staff, and logistics management. Working with distributors reduces upfront costs but impacts long-term revenue. Consider beverage distribution software to streamline whichever path you choose.

Financing and Revenue Planning

Financial planning for a distillery requires understanding both startup capital needs and ongoing revenue opportunities. Your business plan should account for initial funding sources while strategically positioning revenue streams to support growth. Let’s explore the key financial elements you’ll need to consider.

Funding Sources and Opportunities

Beyond traditional bank loans, several funding options exist specifically for craft distilleries:

- Federal and state small business grants: These can provide significant startup capital without requiring repayment, though competition is fierce and application processes are rigorous

- Agricultural development funds: Available in many states for distilleries using local crops, these programs often offer low-interest loans or matching funds

- Crowdfunding campaigns: Following BrewDog’s successful campaign, many distilleries have found success connecting directly with future customers for initial funding

- Industry-specific investors: Angel investors and venture capitalists familiar with the spirits industry can provide both capital and valuable industry connections

- Equipment financing programs: Manufacturers and specialty lenders often offer favorable terms specifically for distilling equipment, helping manage upfront costs

Each funding source comes with its own advantages and requirements. While grants may offer “free” money, they often require detailed business plans and specific usage commitments. Crowdfunding can provide both capital and market validation, making it an increasingly popular choice for craft distillers looking to build community support from day one.

Taproom Investment Strategies

A well-designed taproom can become your most profitable revenue stream. Beyond basic construction costs, consider investments in:

- Bar equipment and draft systems: A quality draft system with multiple lines, proper cooling, and cleaning equipment ensures your product is served at its best and minimizes waste.

- Seating and décor: Comfortable seating and thoughtful atmosphere create an inviting space that encourages customers to stay longer and return often.

- Point-of-sale systems: Modern POS systems do more than just process payments— they track inventory, manage tabs, and provide valuable sales data for better decision-making.

- Staff training programs: Well-trained staff who understand your products and proper serving techniques directly impact customer satisfaction and sales.

- Entertainment options: Features like televisions, sound systems, or space for live music can help draw crowds during slower periods and create a more engaging atmosphere.

The right mix of these elements helps create an inviting atmosphere that keeps customers coming back.

Related: Free Guide: Get Ekos’ Taproom Toolkit

Production Capacity Planning

Your target production volume influences everything from still selection to staffing needs. Consider starting with a system that meets your year-one goals but offers room for moderate expansion. Moving from a smaller still to a medium-sized system is much more manageable than jumping straight to large-scale production.

Understanding these core factors helps create a realistic budget framework for your distillery launch. Remember that each decision affects not just your initial investment but also your ongoing operational costs. So now, let’s talk equipment—this is where things get exciting for most brewers, but it’s also where smart planning really pays off.

Essential Equipment Investments

Aging infrastructure represents a significant investment for distilleries, typically ranging from $150,000 to $300,000. Unlike breweries, distilleries must plan for extended aging periods, particularly for whiskey and other barrel-aged spirits. Your storage facility needs proper climate control to maintain optimal aging conditions and prevent loss through evaporation. The aging warehouse requires specialized equipment including barrel racks, filling stations, and monitoring systems to track each barrel’s progress and maintain quality control.

Many distillers find that aging space quickly becomes a limiting factor for production capacity. A well-designed aging warehouse should allow for efficient barrel rotation and sampling, while maintaining precise environmental conditions. Temperature and humidity control systems represent ongoing operational costs, but they’re essential for protecting your aging inventory investment.

Still Systems and Production Equipment

Your still system represents one of the largest distillery startup costs. How much does a still cost? Professional distilling systems typically range from $100,000 to $400,000, depending on capacity and features. Key considerations include:

- Still size and configuration: Your system’s capacity determines production volume—consider both immediate needs and future growth

- Automation level: While automated systems cost more upfront, they improve consistency and reduce labor costs

- Energy efficiency features: Modern systems may cost more initially but reduce monthly utility expenses

- Hybrid capabilities: Multi-purpose stills allow production of different spirit types, maximizing equipment investment

- Safety systems: Proper ventilation and safety equipment are non-negotiable for distillery operations

Aging and Storage Infrastructure

Aging infrastructure represents a significant investment for distilleries. Unlike breweries, distilleries must plan for extended aging periods, particularly for whiskey and other barrel-aged spirits. Your storage facility needs proper climate control to maintain optimal aging conditions and prevent loss through evaporation. The aging warehouse requires specialized equipment including barrel racks, filling stations, and monitoring systems to track each barrel’s progress and maintain quality control.

Many distillers find that aging space quickly becomes a limiting factor for production capacity. A well-designed aging warehouse should allow for efficient barrel rotation and sampling, while maintaining precise environmental conditions. Temperature and humidity control systems represent ongoing operational costs, but they’re essential for protecting your aging inventory investment.

Licensing and Legal Requirements

Navigating the regulatory landscape for distilleries requires meticulous attention to detail and proper budgeting. The American Craft Spirits Association emphasizes that comprehensive legal guidance is crucial from day one—it’s not just about getting licenses, but understanding the complex web of federal, state, and local requirements.

Federal and State Licensing

Obtaining your distilling license requires dealing with multiple regulatory bodies. Your initial licensing costs, including your distilling license and permits, typically range from $5,000-$15,000, covering everything from federal DSP permits to local fire safety certifications. Here’s what you’ll need to tackle:

- Federal DSP (Distilled Spirits Plant) permit

- State-specific distillery licenses

- Local business permits

- Health department certifications

- Environmental compliance permits

Pro tip: Many successful distillers recommend budgeting for legal counsel with specific distillery expertise. While it adds to upfront costs, it often saves money by preventing costly compliance issues down the road.

Ongoing Compliance an Reporting

Here’s something seasoned distillers wish they’d known earlier—compliance isn’t a one-and-done deal. TTB reporting software helps manage these ongoing requirements by:

- Automating report generation

- Tracking production volumes

- Maintaining accurate records

- Ensuring timely submissions

These systems provide the foundation for maintaining compliance, but tax considerations add another layer of complexity. Understanding tax implications is crucial for your bottom line.

Recent federal excise tax reductions have created new opportunities for craft distillers, with rates varying significantly by production volume. State-by-state taxation adds another layer of complexity—some states offer tax breaks for using local agricultural products, while others impose additional fees on direct-to-consumer sales.

Think of compliance tracking like insurance for your business—it might seem like an unnecessary expense until you need it. Setting up robust systems from day one helps prevent costly penalties and keeps operations running smoothly.

Additional Operational Costs

Beyond initial setup, your ongoing operational costs will shape your distillery’s success. Let’s break down some key areas you’ll need to manage.

Raw Materials Management

For a distillery, this covers more than just your base grains or fruits. You’ll need:

- Base ingredients: High-quality grains, fruits, or botanicals form the foundation of your spirits

- Specialty ingredients: Unique botanicals, flavoring agents, and specialty malts for distinctive products

- Packaging materials: Bottles, labels, caps, and cases for finished product distribution

- Cleaning supplies: Specialized sanitizers and cleaning agents for equipment maintenance

- Quality control materials: Testing equipment and supplies for consistency monitoring

Strategic inventory management is crucial here. The right tracking systems help you maximize value from every ingredient while maintaining the consistency that craft spirits enthusiasts expect.

Related: Find Out How Ekos’ All-In-One Distillery Management Software Can Streamline Your Inventory

Distribution and Storage Systems

Getting your spirits to market requires careful planning and the right tools. Modern beverage distribution software helps streamline this process, but you’ll need to consider several key components:

- Distribution vehicle leasing or purchase: Temperature-controlled vehicles ensure product quality during transport

- Warehouse management systems: Digital tracking solutions for inventory location and movement

- Inventory tracking solutions: RFID or barcode systems for accurate stock monitoring

- Quality control equipment: Testing tools to verify product integrity throughout storage

- Temperature monitoring systems: Automated climate control to maintain optimal storage conditions

These systems work together to protect your product quality and provide the tracking data needed for efficient inventory management. Remember, proper storage isn’t just about keeping bottles on shelves—it’s about maintaining the integrity of your spirits from production to pour.

Technology Investment Strategy

While a beautiful still might be the showpiece of your distillery, don’t overlook the importance of solid tech infrastructure. Modern distillery management software helps optimize everything from production tracking to compliance reporting. Here’s what you should focus on:

- Production tracking: Monitor every step from grain to glass, ensuring consistency and quality

- Inventory management: Keep tabs on raw materials, aging stock, and finished goods

- Quality control: Track key metrics throughout production

- Sales and distribution: Connect your tasting room, distribution, and accounting

- Financial reporting: Monitor costs and profits across all aspects of operation

- Compliance management: Stay on top of TTB requirements and tax calculations

Think of these tech investments as your digital workforce—they’re running 24/7 to keep your operation smooth and compliant. While they represent an additional cost, the efficiency gains typically provide significant ROI through reduced waste and better decision-making.

Professional Development and Training

Success in craft distilling requires specialized knowledge and skills. Leading industry organizations like the American Craft Spirits Association offer comprehensive training programs covering everything from production techniques to business management. The Oregon State University’s Distillery Startup Workshop provides hands-on experience with personalized coaching and practical demonstrations.

Key educational investments include:

- Technical distilling certifications

- Safety and compliance training

- Business management courses

- Quality control certification

- Industry-specific workshops

These educational foundations form the backbone of your distillery’s expertise. Investing in ongoing training not only improves product quality but also helps maintain compliance and operational efficiency as your business grows.

Industry Success Stories

The craft spirits industry has produced remarkable success stories that offer valuable lessons for new distillers. Iconic brands like Johnnie Walker began as small family operations before growing into global leaders. Modern craft distilleries have found success through innovation—companies like BrewDog have leveraged creative funding strategies and marketing approaches to build strong brand recognition.

Key success factors include:

- Strong brand identity: A unique, memorable brand helps craft distilleries stand out in an increasingly crowded market

- Quality consistency: Maintaining product excellence across batches builds consumer trust and loyalty

- Marketing innovation: Creative promotional strategies and digital presence help reach target audiences cost-effectively

- Community engagement: Local involvement and customer relationships create brand advocates

- Strategic growth planning: Careful expansion timing and methods preserve quality while scaling operations

These elements work together to create sustainable growth opportunities. The most successful craft distilleries have shown that maintaining product quality while building strong community connections creates a foundation for long-term success. Their experiences demonstrate that with proper planning and execution, small distilleries can grow into significant market players while maintaining their craft integrity.

Cost-Saving Strategies for New Distillers

Starting small doesn’t mean thinking small. Here are proven strategies from successful distillers to help manage startup costs effectively:

Start Small and Scale Strategically

Begin with essential equipment and add specialized pieces as you grow. Starting with a smaller still that allows for quality production while maintaining profitability makes more sense than overextending initially. Consider creative solutions like obtaining unused bottle molds from manufacturers—these can save thousands in packaging costs while creating unique brand identity.

Smart scaling isn’t just about equipment—it’s about finding innovative ways to reduce costs without compromising quality. Many successful distillers have found that strategic partnerships and resource sharing can significantly reduce initial overhead.

Consider Contract Distilling Options

Some distillers start by partnering with established facilities to build their brand before investing in their own equipment. This approach lets you generate revenue and build customer loyalty while learning the ropes.

Invest in Management Systems Early

Implementing proper distillery software from the start prevents costly mistakes and inefficiencies. Good systems help track inventory, manage production, and maintain compliance without requiring additional staff.

Find Out the ROI of Using Ekos’ Distillery Management Software For Your Distillery

Focus on Inventory Optimization

Proper inventory management prevents both stockouts and excess stock situations. Implement tracking systems that help you maintain optimal levels while minimizing waste.

Develop Strong Supplier Relationships

Building good relationships with suppliers can lead to better payment terms and reliable service. Regular communication helps ensure priority during shortages and can result in better pricing as your volume grows.

Take Control of Your Distillery’s Future with the Right Tools

Starting a distillery requires careful financial planning and the right tools for success. While the initial investment may seem substantial, proper planning and efficient systems can help ensure long-term profitability.

Lay a strong foundation by implementing a comprehensive business management solution to help manage your startup costs effectively and scale your operation efficiently. With features designed specifically for craft spirits producers, Ekos can help you transform your distilling dream into a profitable reality. Get started with Ekos today and discover how the right software can streamline your journey from concept to successful craft spirits business.